Quality requires evidence — not assumptions.

YoY Provenance™ makes the condition, temperature, and mechanical stress of physical products verifiable throughout their entire lifecycle.

Quality Integrity

Quality Integrity

Quality Integrity

Quality does not end with production

Quality does not end with production

Even perfectly manufactured products can lose quality. Not due to production errors, but because of improper temperature control, shocks, unsuitable storage, or deviations during transport. Without reliable condition data, quality remains an assumption — not a verifiable fact.

Even perfectly manufactured products can lose quality. Not due to production errors, but because of improper temperature control, shocks, unsuitable storage, or deviations during transport. Without reliable condition data, quality remains an assumption — not a verifiable fact.

Shock

Authenticity

Humidity

Temperatur

Shock

Authenticity

Humidity

Temperatur

Your benefits

Continuous condition transparency

All condition data is clearly assigned to individual products or shipments and documented throughout their lifecycle. This creates a reliable basis for quality decisions — instead of isolated measurements.

Your benefits

Continuous condition transparency

All condition data is clearly assigned to individual products or shipments and documented throughout their lifecycle. This creates a reliable basis for quality decisions — instead of isolated measurements.

Your benefits

Continuous condition transparency

All condition data is clearly assigned to individual products or shipments and documented throughout their lifecycle. This creates a reliable basis for quality decisions — instead of isolated measurements.

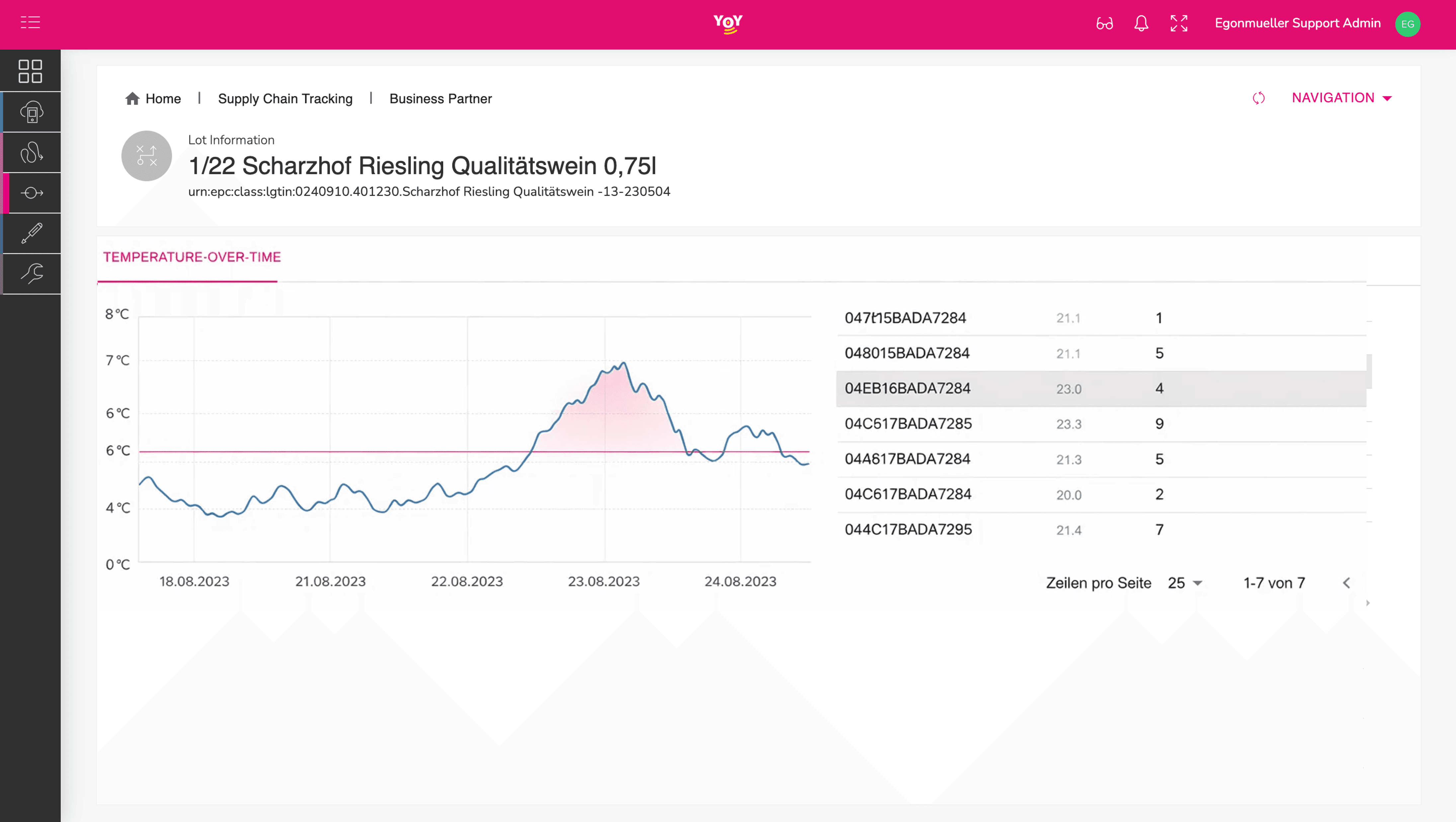

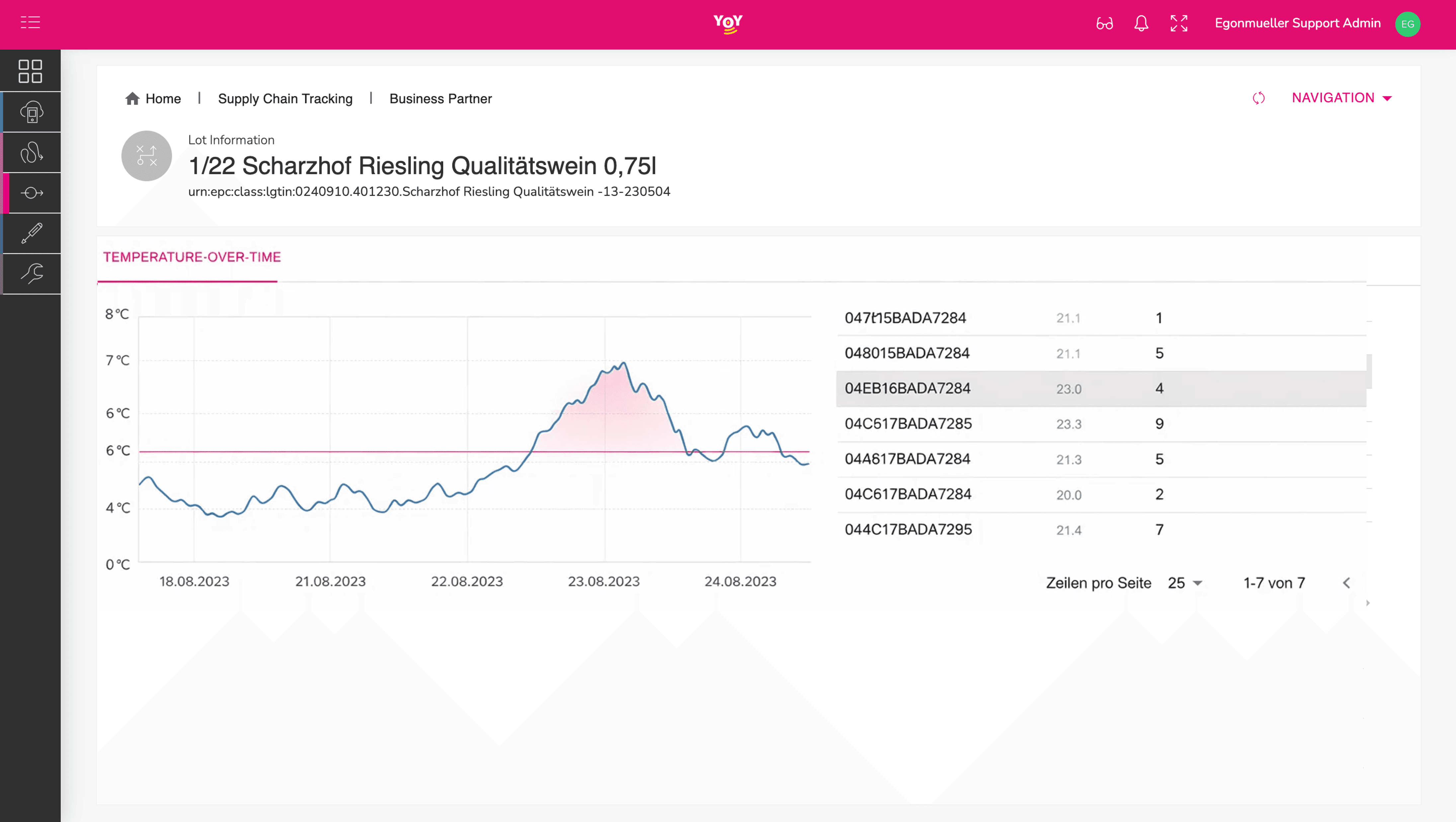

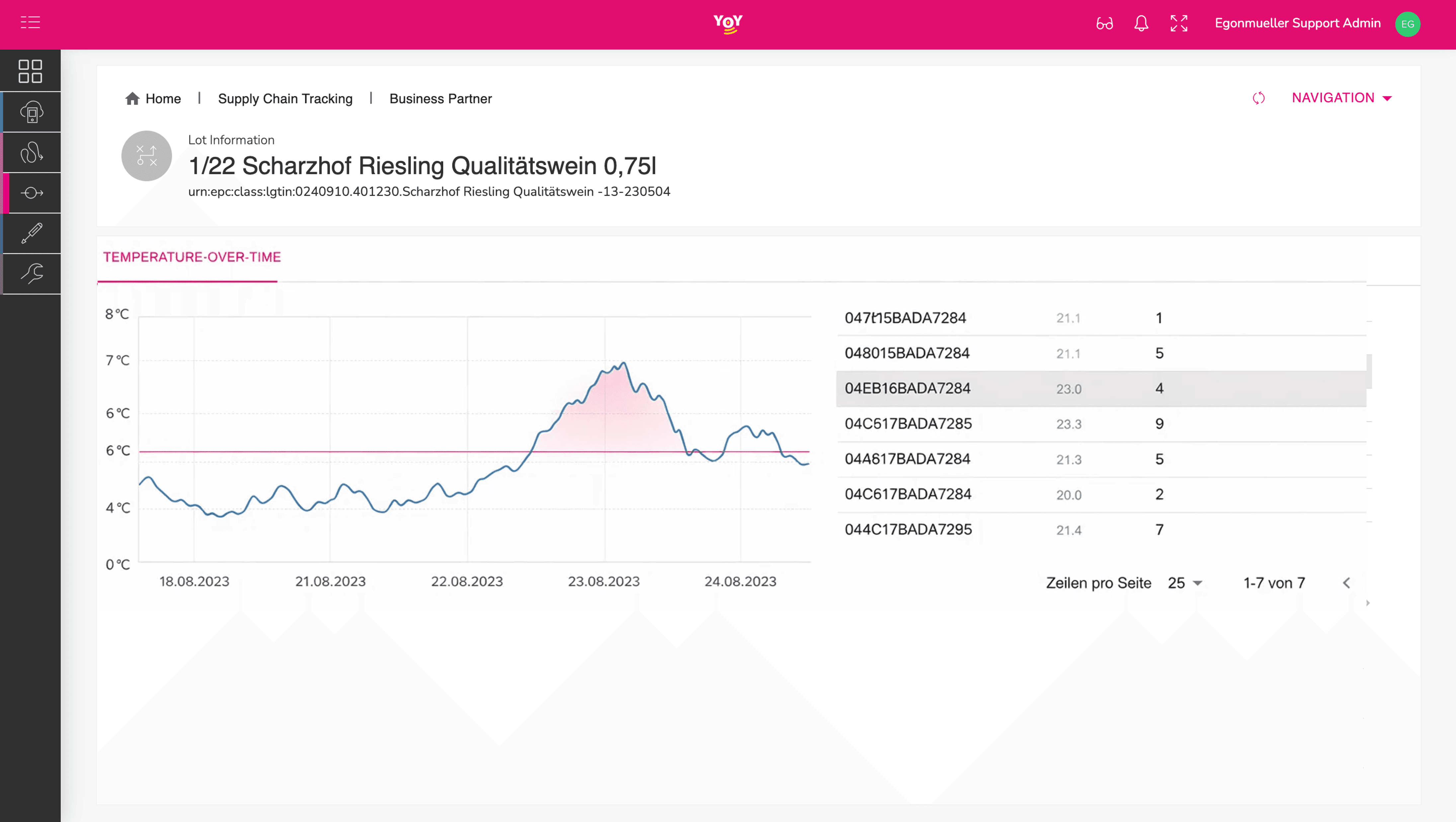

Temperature

Continuous capture of temperature profiles across transport and storage — including the duration and timing of deviations.

Real-Time Tracking

Continuous capture of temperature profiles across transport and storage — including the duration and timing of deviations.

Temperature

Continuous capture of temperature profiles across transport and storage — including the duration and timing of deviations.

Shock

Detection of shocks and mechanical impacts that may affect the quality, functionality, or integrity of a product.

Shock

Detection of shocks and mechanical impacts that may affect the quality, functionality, or integrity of a product.

Shock

Detection of shocks and mechanical impacts that may affect the quality, functionality, or integrity of a product.

Context & timeline

Evaluation of deviations in their temporal and spatial context — not as isolated values, but as a traceable timeline.

Context & timeline

Evaluation of deviations in their temporal and spatial context — not as isolated values, but as a traceable timeline.

Context & timeline

Evaluation of deviations in their temporal and spatial context — not as isolated values, but as a traceable timeline.

How it works

Plug & Play

From filling to interaction — every product remains digitally under your control.

How it works

Plug & Play

From filling to interaction — every product remains digitally under your control.

How it works

Plug & Play

From filling to interaction — every product remains digitally under your control.

1. Apply & Seal

A security label with integrated sensors is applied directly to the product or its packaging and used as a physical seal. From that moment on, the product is uniquely identifiable and its condition becomes measurable.

1. Apply & Seal

A security label with integrated sensors is applied directly to the product or its packaging and used as a physical seal. From that moment on, the product is uniquely identifiable and its condition becomes measurable.

1. Apply & Seal

A security label with integrated sensors is applied directly to the product or its packaging and used as a physical seal. From that moment on, the product is uniquely identifiable and its condition becomes measurable.

2. Capture conditions

Temperature, mechanical stress, and other relevant condition factors are continuously captured and clearly assigned to the respective product or shipment. Evaluation takes place over time, not as a single measurement.

2. Capture conditions

Temperature, mechanical stress, and other relevant condition factors are continuously captured and clearly assigned to the respective product or shipment. Evaluation takes place over time, not as a single measurement.

2. Capture conditions

Temperature, mechanical stress, and other relevant condition factors are continuously captured and clearly assigned to the respective product or shipment. Evaluation takes place over time, not as a single measurement.

3. Detect deviations

Grenzwertverletzungen und kritische Ereignisse werden sichtbar, bewertet und können gezielt adressiert werden – bis hin zu selektiven Maßnahmen oder Rückrufen. Qualitätsentscheidungen basieren auf belegbaren Zustandsdaten.

3. Detect deviations

Grenzwertverletzungen und kritische Ereignisse werden sichtbar, bewertet und können gezielt adressiert werden – bis hin zu selektiven Maßnahmen oder Rückrufen. Qualitätsentscheidungen basieren auf belegbaren Zustandsdaten.

3. Detect deviations

Grenzwertverletzungen und kritische Ereignisse werden sichtbar, bewertet und können gezielt adressiert werden – bis hin zu selektiven Maßnahmen oder Rückrufen. Qualitätsentscheidungen basieren auf belegbaren Zustandsdaten.

See YoY Provenance in action!

In a short demo, we show you how each product is digitally secured.